Embrace Making

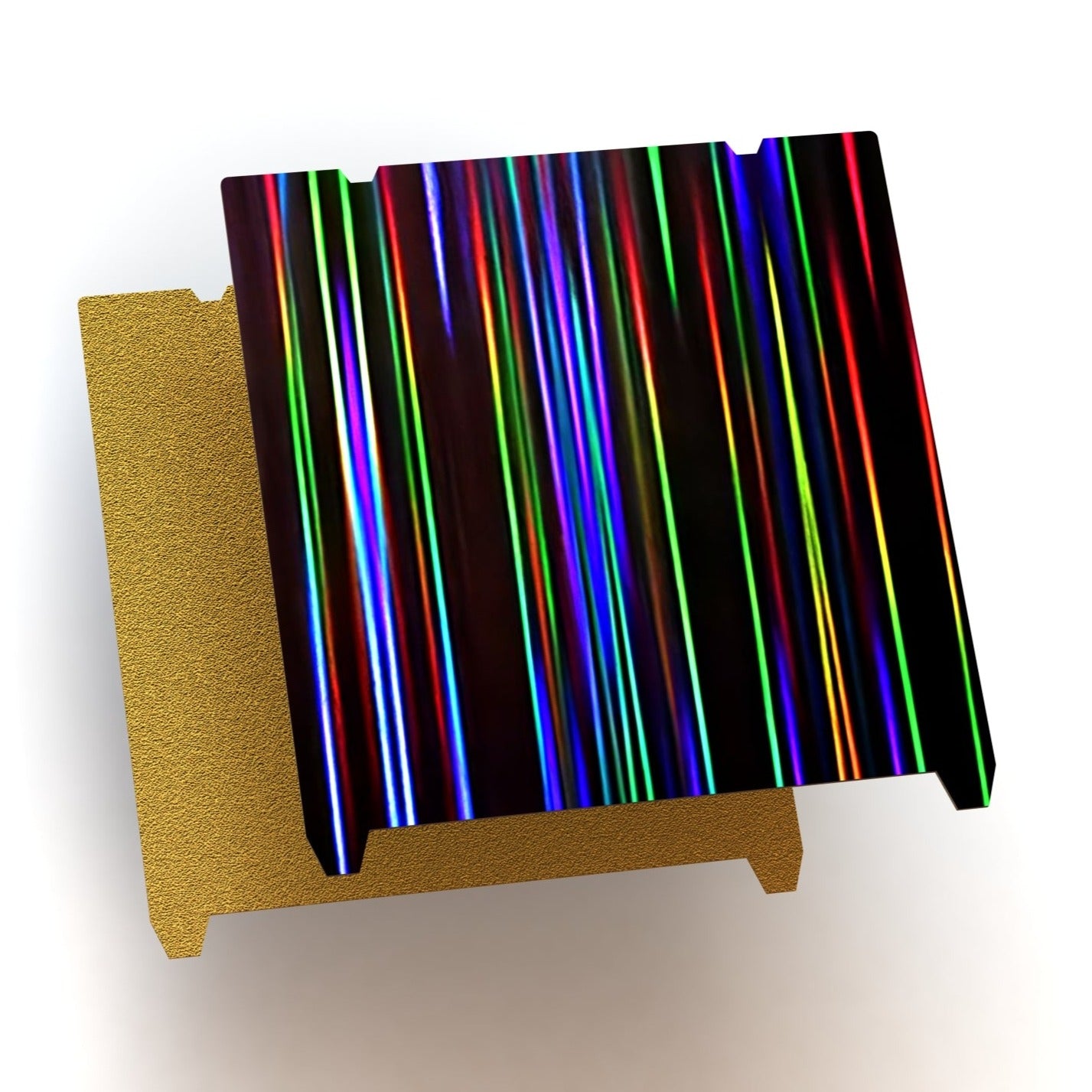

Creality K1, K1C, KE, SE, V3 H1H/PEI (Lightbeam Pattern) Magnetic Flex Build Plate

Choose options

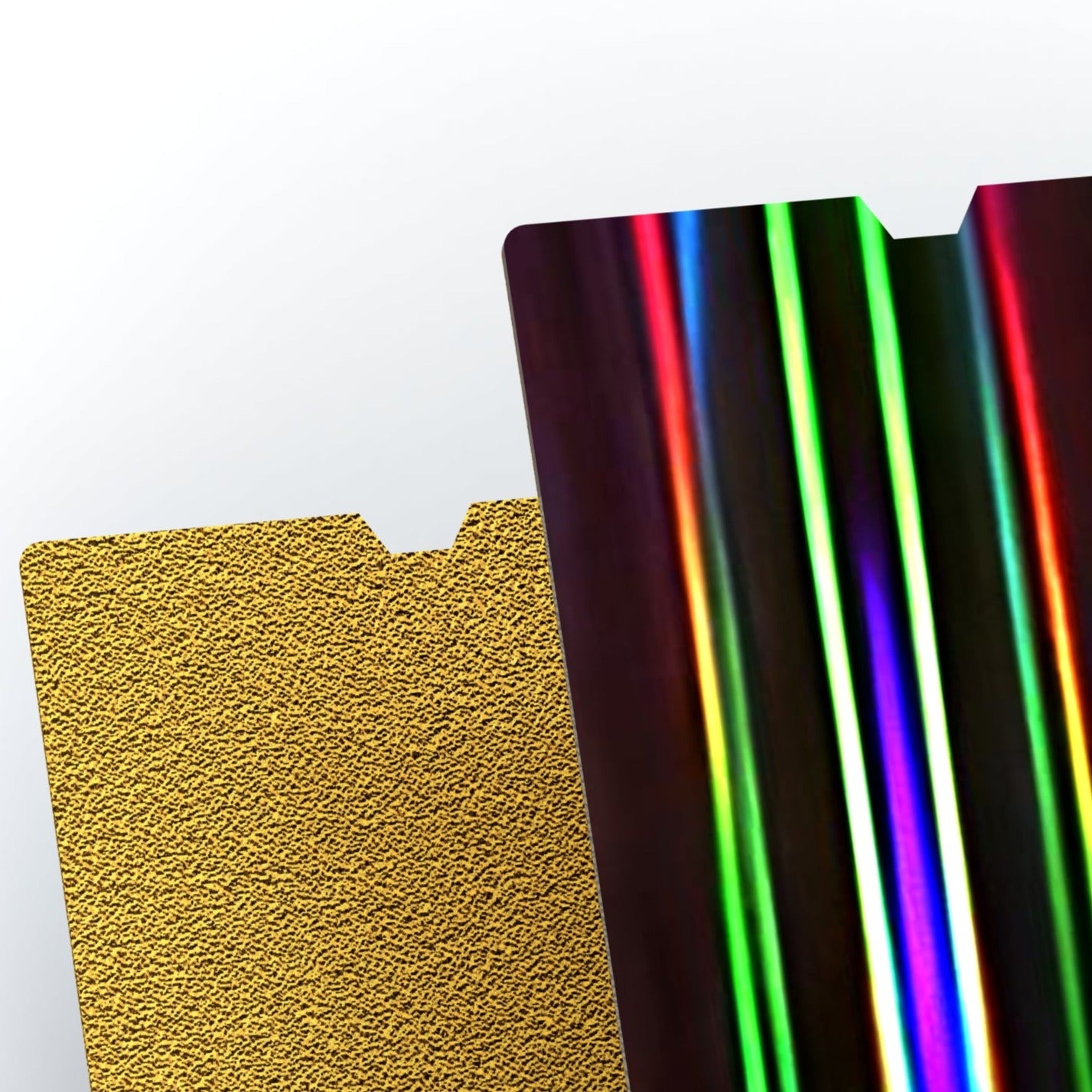

ONE SIDE LIGHTBEAM TEXTURE H1H, THE OTHER SIDE TEXTURE GOLD PEI COATED.

THIS LISTING IS FOR THE REGULAR K1, K1C

WILL ALSO FIT Ender 3 V3, KE, SE, S1

Note that this flex plate will come with the notches at the back to accommodate the locating screws for the K1, Ender 3 V3, KE, SE, and S1!

This listing is not the K1 MAX! This flex plate also comes without the magnetic adhesive sheet since you will not need it for the K1. The K1, KE, SE, S1 already has a magnetic surface.

The original Creality K1C flex plate has a small rubber wiper at the back of the plate. These replacement plates do not have the rubber wiper.

This listing is currently being shipped directly from my supplier and will be shipped separate from any other items you place in your cart. Shipping for this item is FREE.

Make your prints stand out with texture transfer flex plates! These sheets feature one side with H1H coated surface with a geometric pattern. This texture will transfer to the printed surfaces touching the flex plate for a very unique holographic style pattern.

When using the H1H coated side you should not have to increase your build plate temperature to achieve the same adhesion as regular PEI.

H1H is compatible with PLA / TPU /PETG/ABS

AVOID FINGERPRINTS and OILS on H1H surface. CLEAN H1H WITH SOFT WET CLOTH. AVOID ALCOHOL AND AGGRESIVE SOLVENTS. WAIT FOR PLATE TO COOL BEFORE REMOVING YOUR PARTS TO AVOID DAMAGING THE MICROTEXTURE.

The back surface is the tried and true textured gold PEI surface. It is like getting two plates in one.

PEI coated flexible magnetic build plates are one of the best upgrades you can make to any 3D printer to ensure reliable first layer adhesion.

Most 3D printers use glass print beds with or without a special coating to act as an adhesion promoter when hot and will easily release when cold. These generally work well, however, there are some drawbacks to these print beds. One of the biggest issues is that they are often fastened to the print bed carriage using clamps / clips. These components exert force on the glass at the edges and are often the culprit of glass build plates appearing to be bent or bowed. Glass is inherently very flat but it is the fixation system that causes problems.

The magnetic build plates do not have this issue as the magnetic sheet is attached to the print bed carriage using the 3M adhesive backing. Therefore it is uniformly attached without clamps pressing on the corners. The spring steel flex plate uses the magnetic force to adhere itself to the print bed. Again, this is a uniform force across the entire build surface resulting in a very flat surface.

Additionally, removing prints is very easy and is performed with the flex plate removed from the machine. Therefore there is little chance of disturbing the bed level between prints.

What is included:

- Double sided spring steel flex plate

China