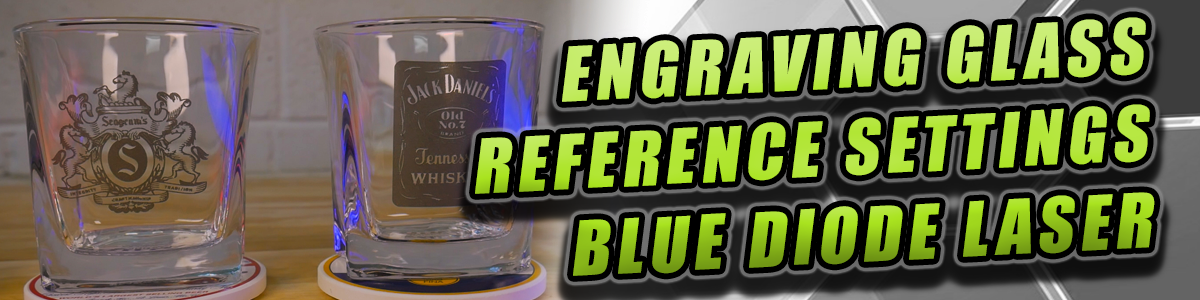

Laser engraving glass has traditionally been impossible with blue diode lasers, however makers and hobbyists have developed innovative surface coatings that can now etch glass surfaces with impressive results. This article explores how to successfully engrave different types of glass using a diode laser and evaluates common surface preparation methods to enhance your results.

🛠️ Why Engraving Glass with a Diode Laser Is Tricky

Glass is a poor absorber of blue diode laser wavelengths (~450 nm), which makes direct engraving inconsistent or ineffective. To overcome this, a surface coating is typically applied to increase energy absorption and reduce thermal stress.

Additionally, different types of glass have varying compositions and thermal properties, affecting how they respond to laser engraving. Let's break them down.

Glass Types & Diode Laser Engraving Settings

⚠️ Important: Settings will vary depending on your diode laser model (power output, lens type, focus, etc.). Always start with test swatches on scrap material and wear proper eye protection. These tests were performed with the 20W blue diode laser of the:

🔥 xTool F1 Ultra

🧪 1. Soda-Lime Glass (Standard Window or Bottle Glass)

This is the most common type of glass used in containers and flat panes.

Laser Settings (Starting Point):

With Laser Marking Paper:

-

Power: 50%

-

Speed: 320mm/s

-

Lines/cm: 140

With Chalk Ink Marker:

-

Power: 50%

-

Speed: 500mm/s

-

Lines/cm: 140

🔥 2. Tempered Glass

Tempered glass is shatters in blunt pieces to avoid cuts. Commonly found on doors, panels, cutting boards.

With Laser Marking Paper:

-

Power: 50%

-

Speed: 250mm/s

-

Lines/cm: 120

With Chalk Ink Marker:

-

Power: 50%

-

Speed: 250mm/s

-

Lines/cm: 120

With Tempera Paint:

-

Power: 55%

-

Speed: 300mm/s

-

Lines/cm: 120

♨️ 3. Borosilicate Glass (e.g., Pyrex)

Borosilicate glass is more resistant to thermal shock, making it more stable during engraving. Great for lab glassware and some kitchenware.

Laser Settings (Starting Point):

With Laser Marking Paper:

-

Power: 55%

-

Speed: 250mm/s

-

Lines/cm: 120

With Chalk Ink Marker:

-

Power: 50%

-

Speed: 250mm/s

-

Lines/cm: 120

💎 4. Crystal Glass (Lead or Lead-Free Crystal)

Crystal glass is softer than soda-lime glass but often more fragile. It typically produces whiter, smoother engravings, but needs finesse.

Laser Settings (Starting Point):

With Laser Marking Paper:

-

Power: 50%

-

Speed: 250mm/s

-

Lines/cm: 140

Surface Coating Methods Compared

To increase the laser’s effectiveness on glass, applying a surface medium helps absorb laser energy and protect the glass from chipping. Here's a comparison of the three most popular options:

🟢 Laser Marking Paper

Pros:

-

Designed specifically for laser marking

-

High contrast and permanence

-

Consistent, professional results

Cons:

-

Time consuming

-

Not reusable

-

High detail designs require tedious removal

🟡 Chalk Ink Marker (Liquid Chalk Markers)

Pros:

-

Fast to apply and remove

-

Good for testing and prototyping

- No ventilation required when applying

Cons:

-

Can result in patchy or lower-contrast marks

-

Varies by brand and layer thickness

-

Less durable than commercial marking sprays

🔴 Tempera Paint (Airbrushed Application)

Pros:

-

Affordable

-

Uniform application with airbrush

-

Works well with many types of glass

Cons:

-

Requires airbrush tool

-

Requires ventilation

-

Time consuming process to apply

- Overspray

✅ Conclusion

Engraving glass with a blue diode laser is absolutely possible with the right approach. By understanding the material you're working with and choosing the proper surface prep, you can achieve clean, detailed engravings even with budget-friendly laser machines. For best results:

-

Always test on scraps or small pieces first

-

Choose your coating based on your project type and budget

-

Keep your laser focused tightly and adjust for glass thickness

-

Protect yourself and your gear—glass can shatter unexpectedly

Have you tried engraving glass with your diode laser? Share your settings and results in the comments below!

🛠️ Materials

As an Amazon associate I may earn a small commission (at NO extra cost to you):

✅ Black Laser Marking Paper (Amazon)

✅ Black Laser Marking Paper (xTool)

✅ Crystal Whiskey Glasses (Set of 6)